Sealcoating protects your paved areas from uv rays, sunlight oxidation damage and penetrating moisture damage. Untreated pavement dries in the sun, becoming weak. The weakened surface erodes slightly, causing openings that let moisture into the deeper layers of the asphalt pavement. Moisture can penetrate the pavement, widening and deepening the cracks. Eventually, you will have a parking lot or pavement surface full of cracks and potholes. The solution is to sealcoat your pavement every 3-4 years, which protects the asphalt from sun and moisture damage.

Weather conditions help determine how well the sealcoat material adheres to pavement, and also how quickly the sealcoat material dries and “cures.” Successful sealcoating requires ideal weather conditions – the temperature, humidity, precipitation and sunlight must all be taken into consideration on the day(s) that you decide to sealcoat. Even the pavement surface temperature makes a difference. Understanding how each condition affects the finished project will make it easier for you to schedule your sealcoating project to get the best results.

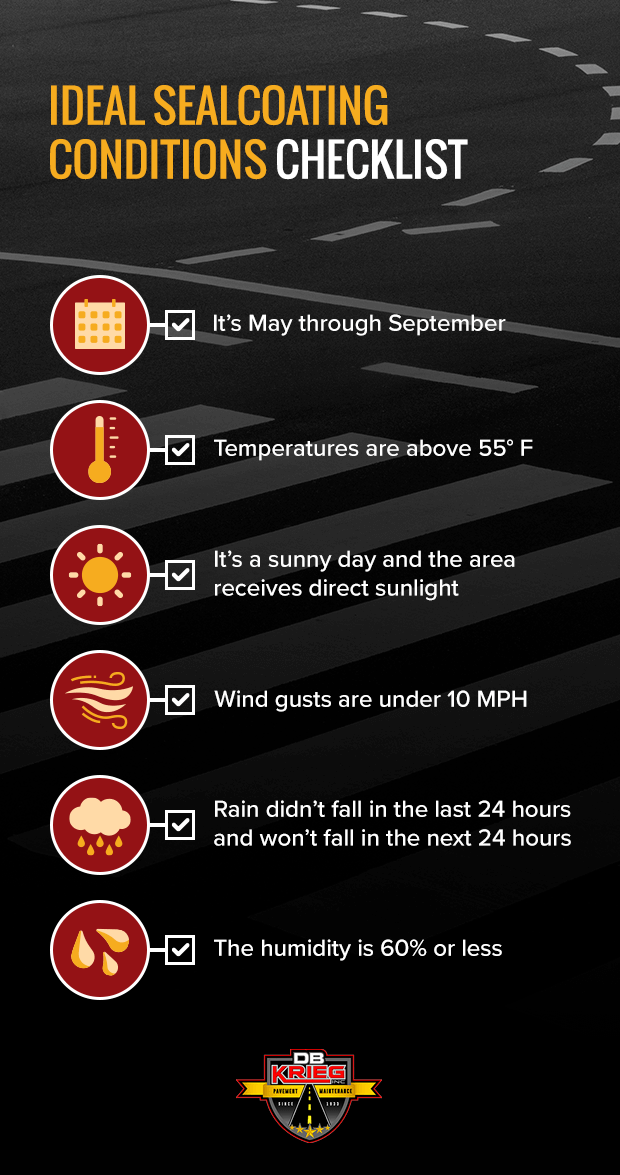

In the Northeast region, the best time of year for sealcoating is late spring and summer (typically May through September.) This is because sealcoating pavement depends on two main factors: temperatures and rainfall. The best time of year to sealcoat blacktop is when temperatures are very warm (70 degrees and rising), conditions are sunny, and humidity is low. All these conditions may not combine perfectly when you need your asphalt sealcoated, but trying to find a day that at least meets dry and sunny conditions is the best weather to seal driveways. At Daniel B. Krieg, our commercial sealcoating professionals take into account what days a customer hopes to have their blacktop sealcoating project done, as well as weather conditions, in order to schedule a time for the job that has high chances of long-lasting protection.

If the weather forecast is calling for rain within 24 hours of the sealcoat being applied, or if rain fell the night before the project, our professionals will not attempt to sealcoat a surface because the water will prevent proper drying.

The best temperature range to seal driveways is between 55 and 90 degrees Fahrenheit. Ideal temperatures are those that start around 70 degrees Fahrenheit in the morning and increase throughout the afternoon. To prevent increasing the drying time and affecting the performance of the finished coating, the temperatures of the surface and the air must be no colder than 55 degrees Fahrenheit at any point within 24 hours of applying the sealcoat material. In most cases, when it comes to the drying time for sealcoating, warmer weather is the ideal weather condition for sealcoating blacktops.

NO, you cannot sealcoat asphalt in the winter (in the Northeast region of the U.S.) The best months to sealcoat are May through September. Most manufacturing plants in the Northeast are shut down in the winter, due to the fact that the sealcoat material cannot be applied in cold temperatures.

Temperatures below the minimum 50 degrees Fahrenheit are too cold for sealing driveways. Furthermore, if the low temperatures fall to freezing or below while the coating dries, water in the sealcoat material could freeze, leading to the finished product separating and peeling. The Central and Southern Pennsylvania counties we serve do not qualify for sealcoating during the winter season due to low temperatures.

Just as cold weather affect the integrity of sealcoating, so can excessively hot conditions. Temperatures above 95 degrees Fahrenheit can bake the sealcoat before the material properly adheres to the pavement. The binder used in many sealcoatings can melt at temperatures above 100 degrees Fahrenheit. To avoid these problems, always choose a professional sealcoating contractor with the experience to know how to deal with Pennsylvania’s temperature swings.

Sealcoat material needs direct sunlight to properly dry. Mostly-cloudy conditions that keep sunlight from reaching the coated surface will lengthen the drying time, or can even prevent the sealcoat from drying at all. For the best performance, the sealcoat material must have direct sunlight for the majority of the drying time. Cloudy conditions throughout the day could reduce the quality of the coating after it dries.

Additionally, clouds indicate higher humidity in the air, and prime conditions require low moisture to allow the water in the sealcoating to evaporate. High humidity levels mean the air cannot absorb as much moisture compared to when it’s drier. Because clouds form from water vapor, cloud cover could indicate humidity is too high for proper curing of the sealcoating on your asphalt surfaces.

Humidity makes a drastic difference in how quickly the sealcoat material dries. Water in the coating must evaporate into the air, but when moisture saturates the air, drying time slows down significantly. Lower humidity levels hasten drying times. The humidity levels make such a difference that a few percentage points could double the drying time. Ideal humidity levels are below 60 percent.

On a comfortably dry day with 40 percent humidity, the sealcoat material may dry at a reasonable pace. However, if the moisture doubles to a muggy 80 percent, the drying time triples. If you must close your parking lot for a given time during the sealcoating process, higher humidity levels could mean increasing the time you have the area blocked off. The sealcoat will eventually dry in humid conditions, as long as it does not rain, but you will need to plan for more drying time.

Another aspect of humidity you must consider is fog. Fog forms when humidity reaches 100 percent, creating ground-level clouds. If fog covers the area you will coat in the morning, your contractors must wait until the fog clears, the surface dries and the temperatures warm.

You can not sealcoat a driveway in the rain. Sealcoat material will not properly adhere to the asphalt pavement if it is wet. Asphalt must be 100% dry in order to apply the material. Sealcoating application and drying do not pair well with rainy or even misty conditions. Rain prevents the coating from drying. Depending on how heavily the rain falls, it could also wash away the sealcoating from the surface before it has had enough time to dry.

Because moisture on the surface may prevent the coating from adhering and drying properly, please turn off any nearby sprinklers before we sealcoat your pavement. Also, note that rain has such a severe impact on the quality of blacktop sealcoating that we won’t treat your surfaces if rain is in the forecast or has fallen within 24 hours before or after sealing your driveway. Of course, our office will reschedule with you for a time when the weather cooperates better.

Warmth and sunshine are crucial for a sealcoat material to dry fully and properly. Total shade prevents drying. Furthermore, areas that never see any sunshine tend to have cooler surface temperatures.

Shady areas need at least two hours of the afternoon sun to dry adequately. Spots in continuous shade will not cure thoroughly. When surface temperatures remain around 50 degrees or colder, which is more likely in areas without sunlight, the coating’s success diminishes drastically.

Sealcoatings dry from top to bottom, which requires heat and light from above to draw moisture up through the layers of the coating and into the air. Even hot surfaces in constant shade will not have enough light from the top to draw water out of the sealcoating. Therefore, we cannot guarantee that areas of your commercial parking lot that never receive direct sunlight will dry or perform properly.

When debating on sealcoating your commercial driveway at night vs. day, there are many factors to consider. While sealcoating your parking lot at night may be more convenient for your business, it does not mean the coating will dry during the nighttime hours. Sealcoating require direct sunlight for proper curing. Even if the pavement surface feels dry to the touch, the sealcoat material still needs curing time in sunny conditions to perform as expected.

Sunlight also makes it easier for the sealcoating crew to work. At night, a lack of light can severely hamper the pace at which the crews apply the sealcoat material. At Daniel B. Krieg, we do not offer sealcoating services at night. It is our professional opinion that sealcoating at night will not provide our customers with the highest quality finished product.

Wind simultaneously offers benefits and problems for sealcoating crews. While breezy weather may help expedite drying time, it also can cause severe issues during the application of the material. If winds gust above 10 miles per hour during the spraying process, the coating may get blown onto nearby vehicles or buildings, which can result in costly damage. Because we strive to give you the best service without causing harm to other parts of your property, Daniel B. Krieg, Inc. will NOT apply sealcoat material on windy days. We will contact you to re-schedule your project for another day when the weather conditions are better.

You should allow at least 24-48 hours for an asphalt sealcoat to dry. However, how long it takes asphalt sealer to dry varies based on the conditions of that particular day. Factors that impact the time it takes to completely dry include:

Always remember that patience is key to a strong sealcoat that will protect your asphalt surface for years to come.

The conditions outside determine how well the sealcoat material cures. To understand why weather conditions are so crucial, you must know how the coating dries and cures.

First, curing and drying are not interchangeable. These separate processes must both happen for the sealcoating to perform as expected. Sealcoatings have a portion of their volume composed of water. For the curing process to occur, the coated surface must dry completely. Despite being a liquid, the coating acts like a laminated surface with layers of differing moisture content after application. Once all these layers release their moisture, curing can happen.

Because lower layers of water must move to the top, as the surface dries, finishing the process will take longer. The majority of the moisture leaves the coating relatively quickly, but the final minor part of the moisture will need extra time to leave the sealcoating.

Drying occurs as moisture from the coating leaves the surface from top to bottom. As water evaporates from the top layers, more from the bottom drifts to the top to later get absorbed into the air. While drying will make the coating dry to the touch, the surface may still have dry surface may not attain the hardness from proper curing. You could track coating on your shoes or cause damage with vehicle tires if you open the area too quickly.

For review of the above information, run over our checklist to see if your commercial parking lot is ready for sealcoating!

Weather accounts for the most restrictive factor when it comes to sealcoating. While we understand that re-scheduling a project can become frustrating for our customers, we appreciate your cooperation as we try our best to complete your project under the best conditions. Our professionals will make every effort to schedule your sealcoating on a day with prime conditions. The materials we use include the trusted Sealmaster® brand. Our materials, service and reputation of 90+ years of experience has ranked us as a top contractor in Pavement Maintenance Magazine. We also are fully insured and a prequalified PennDOT contractor.

If you want professional service, contact us at Daniel B. Krieg, Inc. for a FREE quote for your parking lot maintenance project.

Please contact Daniel B. Krieg, Inc. by filling out the form below, or by calling us at one of our locations.