Commercial Crack Filling Services in Harrisburg, PA

FREE Estimate >>High-quality, professional crack filling services —Guaranteed!

For more than 90 years, Daniel B. Krieg has served Harrisburg, York, Mechanicsburg, Camp Hill, Carlisle, Lancaster, Hershey and the surrounding Central Pennsylvania community with outstanding asphalt and pavement maintenance services. When you choose Daniel B. Krieg, you can count on professional and efficient crack filling and crack repair services from a deeply experienced team of experts. We use the most effective PennDOT-approved rubberized crack filler to extend the life of your pavement and save on future expenses.

FREE Crack Filling Estimate >>

Table of Contents

Our Guarantee

Our work features a one-year satisfaction guarantee on workmanship and materials, so you can benefit from further peace of mind as you protect your paved surfaces. Our goal is 100% customer satisfaction!

Crack Filling Questions You Might Have

Unfortunately, cracks are inevitable at some point over the lifetime of your pavement. Are you wondering when to do pavement crack filling and what it involves? Get started with the help of Daniel B. Krieg and these frequently asked questions about crack filling:

1. How frequently should you do crack filling? On average, you should have pavement cracks filled once each year by a professional company.

2. Can you fill every type of crack? You can only fill straight-lined cracks as opposed to alligator cracks.

3. Why not alligator ones? Alligator cracks indicate subbase failure in the pavement. This means that areas of "alligatored" or "spiderwebbed" cracking will need to be removed and replaced.

4. How long does it take to dry? Crack filling material sets up in just a few minutes, meaning there is very minimal interruption to your parking lot as we complete the work.

5. Why do some cracks re-open? Re-opening can occur during the freeze-thaw cycles throughout winter, because the cold weather causes excessive contraction and expansion to occur.

6. How does the process work? We apply the PennDOT-approved, rubberized crack filling material at 300 degrees F using Crafco and Cimline oil-jacketed kettles.

7. Does a sealcoat hide crackfiller? No, you will still see the crackfiller through the sealcoat, as it takes on a darker color.

8. Why invest in crack filling? Crack filling will save you significant money in the long-run, because it prevents further damage to your pavement that can lead to very expensive repairs (potholes, alligator cracking, subbase failure, etc.) Crack filling is the MOST cost-effective pavement maintenance solution.

Parking Lot Crack Filling Products

There are a variety of different crack filling products available to consumers. These products vary based on temperature flexibility, crack size, polymer and rubber components and application goals. Daniel B. Krieg offers a number of parking lot crack sealant products to best suit different scenarios. Specifically, it matters what equipment is used to apply the crack repair sealant, what size the cracks are and whether the crack sealant material is being applied to asphalt or concrete. The details below will help clarify the differences between our crack filler materials.

1. Rubberized Parking Lot Crack Sealant — #1190

Rubberized parking lot crack sealant is a hot-applied asphalt-based product used to seal and fill cracks and joints in asphalt and concrete pavements. This product is created with asphaltic resins, synthetic polymeric rubber, plasticizers, stabilizers and reinforcing fillers. Rubberized crack sealant is designed to expand and contract throughout the freeze-thaw cycles of winter and summer. From extreme heat to freezing temperatures, you can count on rubberized crack filling material to keep your cracks protected.

Rubberized crack sealant is specifically used in highway, street and airfield pavements. It is applied to pavement cracks and joints using either pressure-feed melter applicators or pour pots.

Technical specifications for rubberized crack sealant include:

- ASTM D-6690, type I

- ASTM D-1190

- AASHTO M-173

- FAA P - 605

- FED SPEC SS-S-164

Benefits of Rubberized Parking Lot Crack Sealant

Rubberized parking lot crack sealant serves as an affordable solution for sealing concrete and asphaltic pavement surfaces. This is a strong preventive maintenance compound that keeps surfaces safe from moisture to prolong the life of the parking lots you use for your commercial business. You will also notice outstanding results after freezing and thawing cycles.

This material comes in 30 to 50 lb. boxes and should be melted in an oil-jacketed kettle or melter before it is applied at 380 degrees Fahrenheit. The crack sealant can be reheated multiple times if needed.

2. Dura-Fill P.L. Parking Lot Crack Sealant

Dura-Fill P.L. is another specialty-grade crack sealing product that we have available in 30 lb. boxes. This product is well-suited for parking lots and driveways. You may apply it at 370 to 390 degrees Fahrenheit using either an oil-jacketed kettle or a direct-fired kettle with mechanical agitation.

Advantages of Dura-Fill P.L. Parking Lot Crack Sealant

Dura-Fill P.L. allows you to work with portland cement, asphaltic pavements and parking lots. The product is engineered to assist with sealing expansion and contraction joints, random cracks, longitudinal and transverse cracks, as well as joints near concrete and asphaltic shoulders.

Professionals enjoy using Dura-Fill P.L. parking lot crack sealant because of its favorable characteristics, such as:

- Quick-melting properties

- Flexibility at temperatures as low as -10 degrees Fahrenheit

- Low penetration capabilities

- Self-leveling qualities

Why Choose Daniel B. Krieg?

When you partner with Daniel B. Krieg, you are in the best of hands. We are committed to building lasting business relationships with our customers by providing them with a wealth of service benefits, such as:

- Excellent customer service: We invest in our employees by equipping them with the skills and knowledge to handle any repairs with ease. Our team also goes above and beyond for our customers, ensuring their needs are met.

- Industry-leading experience: Our business has over 90 years of industry experience, so you can trust us to maintain your commercial parking lot.

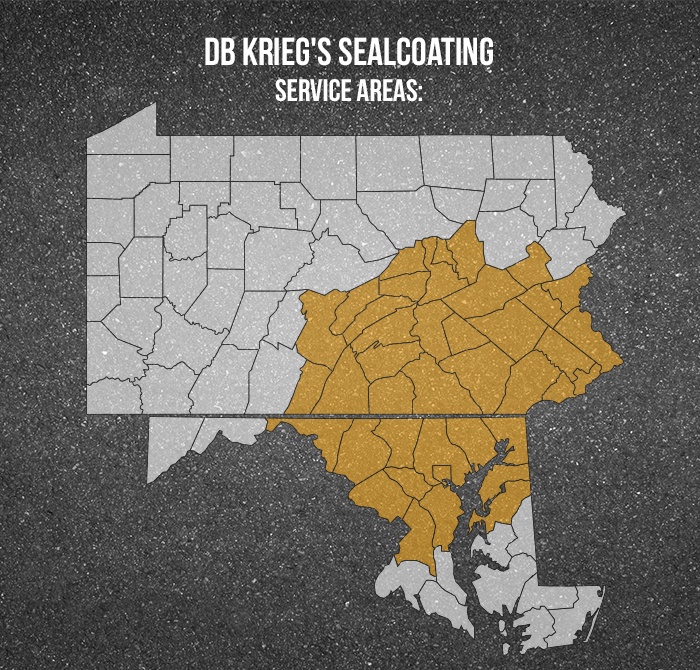

- Extensive reach: We are proud to serve a wide array of areas within Pennsylvania and Maryland, and we strive to continue growing so that we can provide our expert services to more businesses.

- Innovative practices: Our excellent results are possible due to our advanced equipment, effective strategies and high-quality materials.

- Trusted suppliers: To ensure we give our customers the best results possible, we build partnerships with trusted brands, such as SealMaster®, for premium sealing and crack filling materials.

Learn more about crack filling Repair

Choose from the drop-down menus below to learn more about crack filling and our company:

How Do I Know When It Is Time to Crack-Fill?

Once cracks have begun to occur in the pavement, the property owner is officially "on the clock" with regard to instituting a crack filling program. You should fill cracks within one season of their first appearance. When your cracks grow to more than 1/8", they need to be addressed immediately. The key to protecting your pavement is being proactive.

Once cracks have begun to occur in the pavement, the property owner is officially "on the clock" with regard to instituting a crack filling program. You should fill cracks within one season of their first appearance. When your cracks grow to more than 1/8", they need to be addressed immediately. The key to protecting your pavement is being proactive.

Failure to repair asphalt cracks soon enough can lead to more severe damage, like potholes, which will cost more to repair and may require you to repave your parking lot. Another proactive method of dealing with asphalt damage is preventive maintenance. As a property owner, creating a pavement maintenance plan helps improve the longevity of your parking lot and reduces the chance of unexpected damage.

What causes pavement cracks?

Due to Mother Nature, the formation of pavement cracks cannot be avoided. The sun dries out the pavement, creating small areas for water to seep through. During the winter months, this water will freeze, expand and cause pavement cracks to form and grow larger. If left untreated, pavement cracks will eventually lead to very costly damage, such as accelerated deterioration, tenting, raveling and potholes.

This means that pavement cracks MUST be routinely maintained to avoid deterioration and costly repairs. On the other hand, if pavement cracks are not properly filled, they will only continue to get worse and eventually destroy your pavement.

Our team of highly experienced professionals is ready to keep your pavement in the best possible condition with our advanced equipment and highly engineered materials.

Our materials

We use a highly engineered, PennDOT-approved, rubberized crack filler that is designed to expand and contract with pavement cracks. Our crack filler is formulated with asphaltic resins, synthetic polymeric rubber, plasticizers, stabilizers and a blend of organic reinforcing fillers. This material has a high resiliency to freeze/thaw cycles and has proven to provide excellent results under extremely varying conditions.

Our crack filler material can be used on roadways, highways, parking lots, driveways and airport runways. It meets the following specifications:

- ASTM D-6690, Type I

- ASTM D-1190

- AASHTO M-173

- FAA P-605

- FED SPEC SS-S-164

Our Process

At Daniel B. Krieg, we use 185 CFM compressed air to thoroughly clean each crack, creating a clean reservoir for the sealant to bond. We'll walk the length of the entire crack, ensuring that every inch of the area is free from dirt and debris.

We then fill the cracks using a pressurized wand with PennDOT-approved rubberized crack and joint sealant. Our highly skilled professionals make sure that the entire crack area receives the correct amount of filler and a uniform sealant layer.

Unlike our competitors, we do not just "overband" your pavement cracks. Our process is PennDOT-approved and ensures the longest-lasting seal. After we apply the sealant, your pavement will be ready for use in minutes.

Crack Filling Process - Step 1

Crack Filling Process - Step 2

Our Equipment

We use only the most advanced applicator equipment

- Crafco Super Shot 250 Units with Compressor, Auto Loader and Heated Hose

- Crafco EZ1500 Series Units (400 Gallon Capacity) with Compressor, Auto Loader and Heated Hoses

- All Crack Filling trucks in our fleet are equipped with 185 CFM utility air compressors (100 psi)

When can crack filling be done?

Typically the winter months of November through March are off-peak for pavement maintenance services. The reason for this is low temperatures, snow/moisture, salt and snow plows, etc., which can make operations difficult. We typically start crack filling in April for the best results. The conditions in which crack filling is completed are crucial to ensure a long-lasting finished product. Pavement cracks must be completely dry in order for the material to adhere to the pavement.

What areas do you service?

Pennsylvania counties: Adams County, Bedford County, Berks County, Blair County, Bucks County, Carbon County, Centre County, Chester County, Clinton County, Columbia County, Cumberland County, Dauphin County, Delaware County, Franklin County, Fulton County, Huntingdon County, Juniata County, Lackawanna County, Lancaster County, Lebanon County, Lehigh County, Luzerne County, Lycoming County, Mifflin County, Monroe County, Montgomery County, Montour County, Northampton County, Northumberland County, Perry County, Philadelphia County, Schuylkill County, Snyder County, Sullivan County, Union County, Wyoming County, York County. Maryland counties: Anne Arundel County, Baltimore County, Baltimore City County, Carroll County, Cecil County, Frederick County, Harford County, Howard County, Kent County, Montgomery County, Prince George's County, Queen Anne's County, Washington County.

Our Locations

Harrisburg Office

- 4200 Paxton Street

Harrisburg, PA 17111 Map It >> - Mon - Fri: 7:00 am - 4:00 pm Sat: 7:00 am - 11:00 am Sun: Closed

- 800.334.4929

717.564.2400

Fax: 717.558.2036 - Contact Us

York Office

- 3331 Gulton Road

York, PA 17404 Map It >> - Mon - Fri: 7:00 am - 3:30 pm Sat: 7:00 am - 11:00 am Sun: Closed

- 717.792.0284

Fax: 717-792-0640 - Contact Us

Other Helpful Tips

Once your asphalt has been resurfaced, be sure to ask us about other forms of preventive maintenance to protect your investment and to keep your parking area looking its best. Our preventive maintenance services include:

This protective material stops weather damage, prevents oxidation, beautifies pavement...

Learn More >>

Traffic signs, U-channel posts, round posts and all safety devices will protect your business...

Learn More >> Back To Top

Back To Top